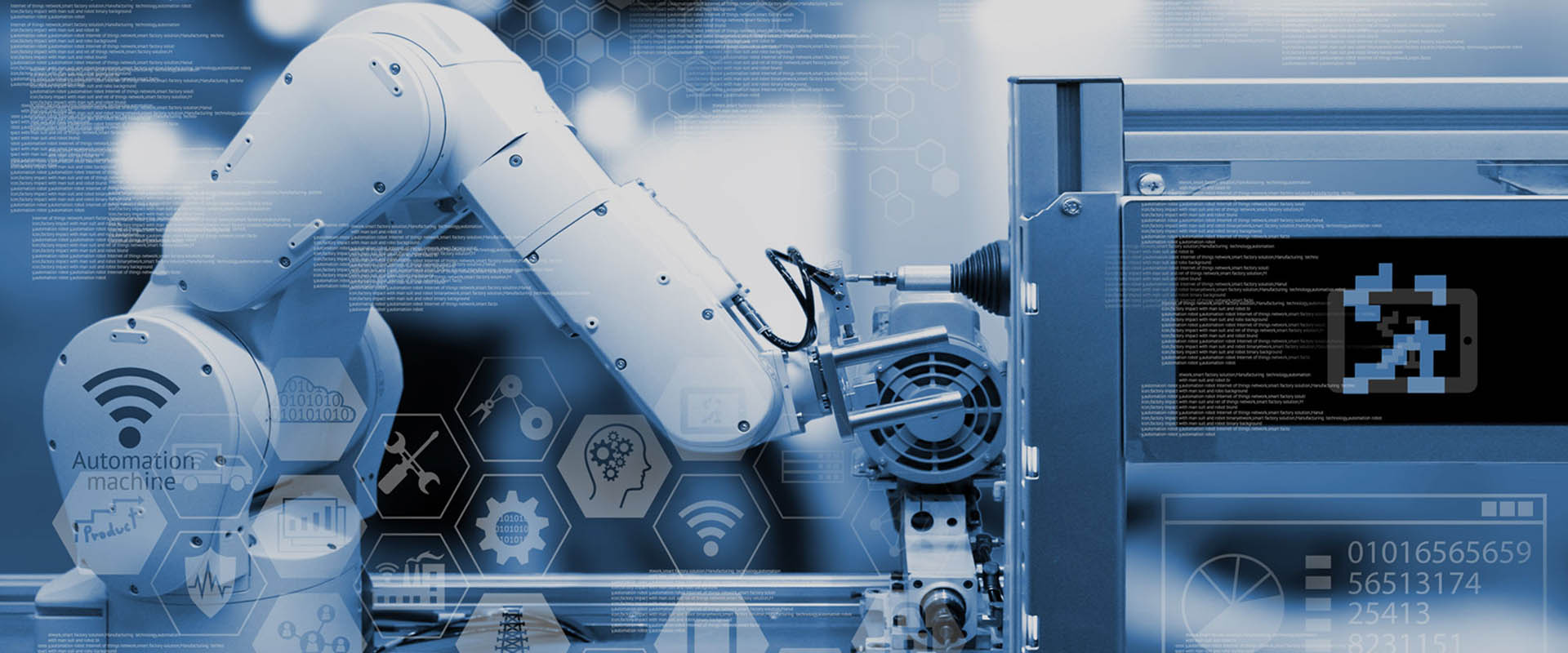

Industrial Robot

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on two or more axes.

Typical applications of robots include welding, painting, assembly, pick and place for printed circuit boards, packaging and labelling, palletizing, product inspection, and testing; all accomplished with high endurance, speed, and precision. They can help in material handling and provide interfaces.

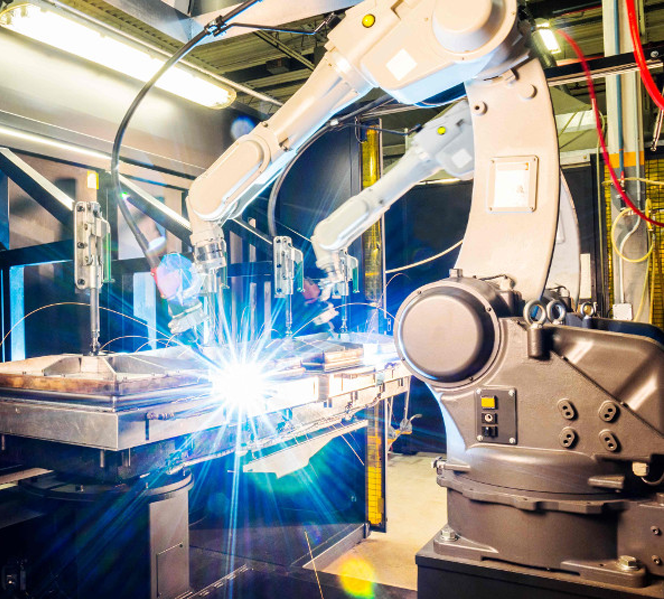

Robot Welding

Robot welding is the use of mechanized programmable tools (robots), which completely automate a welding process by both performing the weld and handling the part. Processes such as gas metal arc welding, while often automated, are not necessarily equivalent to robot welding, since a human operator sometimes prepares the materials to be welded. Robot welding is commonly used for resistance spot welding

Assembly Robot

Assembly robot is the core of flexible automated assembly system equipment, robot manipulator, controller, the end of the actuator and sensor system components. The controller adopts multi-CPU or multi-level computer system to realize motion control and motion programming

Picking and Packing Robot

Applications in packaging are vast and varied including but not limited to tray packing, tray handling, case packing, case erection and handling, bottle packing, shrink-wrapping, pouch handling and packing and so on. Software that combines the vision and tracking with built in part scheduling in case you application requires multiple robots synchronizing the operations for tray-packing, singulating and more.